FM-I PRO: Custom EPDM Granules for Turf Infill Series | High performance sports turf

- Model

- FM-I PRO

Item specifics

- Base polymer

- EPDM (Ethylene Propylene Diene Terpolymer)

- Color range

- Jaguar Series

- Tensile strength

- 10.7Pa

- Elongation at break

- 700%

Review

Description

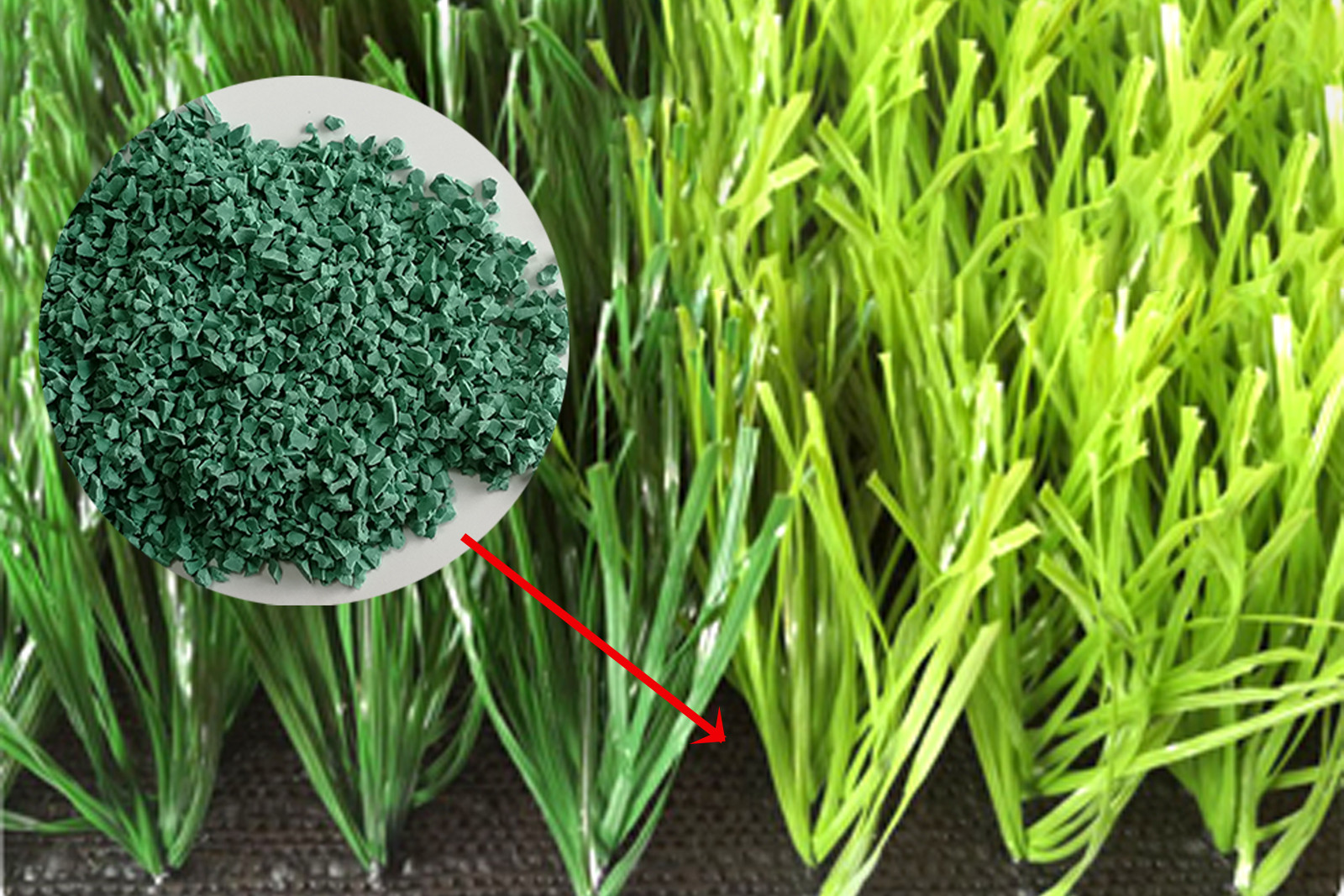

Epdm Granules Introduce

Elevate Turf Performance with FieldsMaster Turf Infill Granules

Fieldsmaster EPDM Granules for Turf Infill are well made to enhance the performance of modern artificial turf. Our infill granules are made from high-quality EPDM rubber, which ensures optimal functional sports characteristics, including excellent ball roll and bounce performance, outstanding damping properties, traction and injury protection. With Fieldsmaster turf infill granules, you can take your turf course to the next level of performance and safety.

Epdm Granules Technical Data Sheet

Property | Value | Unit | Standard | / |

Tensile strength | 10.7 | MPa | DIN 53504(2017) | / |

Elongation at break | 700 | % | DIN 53504(2017) | |

Hardness | 60 ± 5 | Shore A | ISO 48-4(2018) | |

Density | 1.36± 0.03 | g/cm3 | DIN EN ISO 1183-1(2019) | |

Bulk density | 574 | g / L | EN 1097-3(1998) | |

Grey Scale Assessing | 4-5 | \ | DIN EN 20105-A02(1994) | |

Base polymer | EPDM – ethylene propylene diene monomer rubber | |||

Content: EPDM - Etylen Propylen Dien Monomer, mineral fillers, plasticizer, vulcanising agents, additives, pigments | ||||

Flammability class | Ⅰ | GB/T22517.62020 | ||

Epdm Granules Environmental Parameters | |

Standard | Result |

GB 36246-2018 Toxic substance(Total 18 PAHs) | Fulfills requirements |

(EC)No.1907/2006(REACH)SVHC | Fulfills requirements |

EN 71-3:2019+A1:2021- Migration of certain elements | Fulfills requirements |

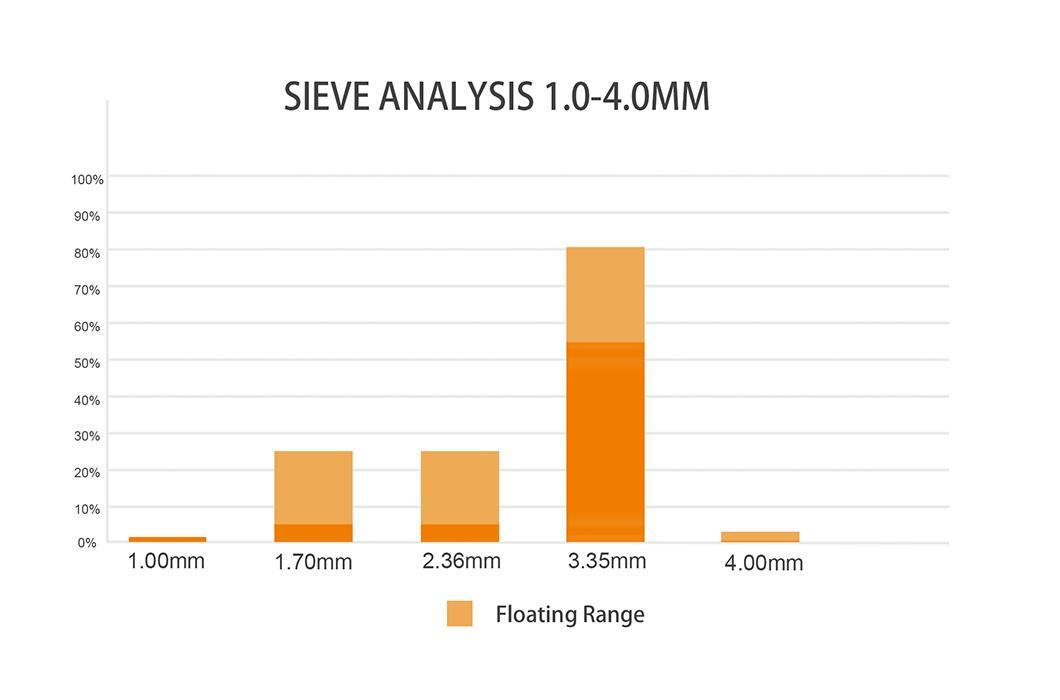

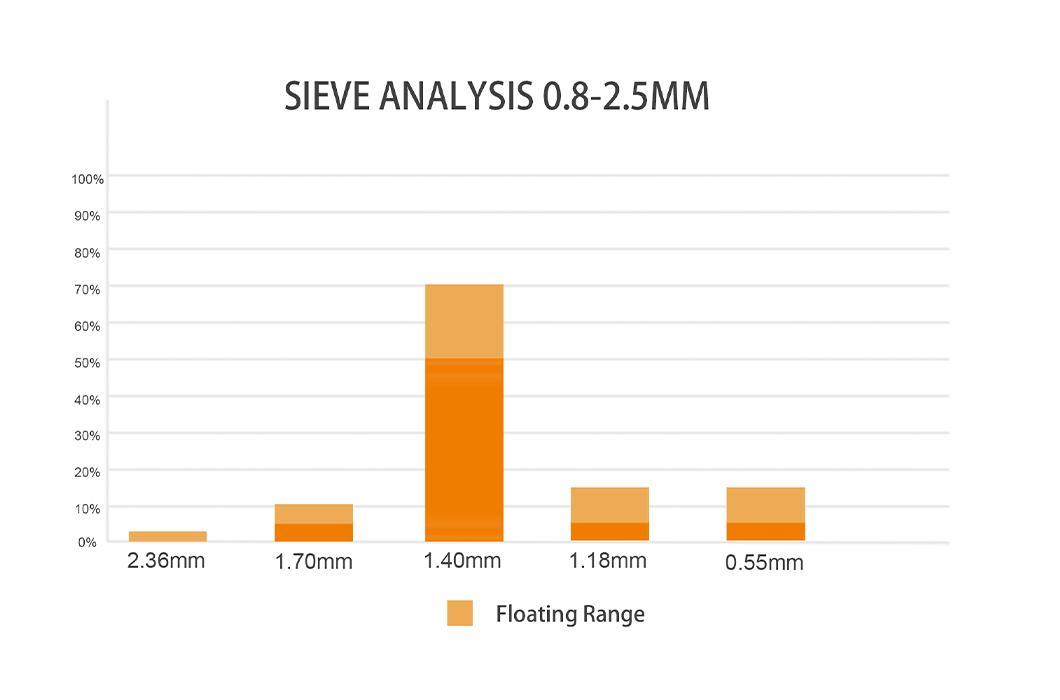

Epdm Granules Sieve Analysis

Epdm Infill Granules Application

Epdm Granules After-Sale FAQ

Q: What After-Sales Service Is Available?

A: Warranty period: The warranty period specified in the sales contract is usually a certain number of years, such as one year, two years or more.

A: Warranty period: The warranty period specified in the sales contract is usually a certain number of years, such as one year, two years or more.

Warranty scope: The warranty covers quality problems and manufacturing defects of EPDM granules under normal use conditions, such as particle breakage, discoloration, hardening, etc.

Warranty responsibility: The supplier or manufacturer assumes the responsibility of repairing or replacing EPDM particles with quality problems during the warranty period to ensure that the product achieves the expected use results.

Exclusion of liability: If damage or failure within the warranty period is caused by improper use, incorrect installation, natural disasters, etc., it is not covered by the warranty.

Maintenance services: Warranty services provided by suppliers or manufacturers include free maintenance, replacement of particles or provision of relevant technical support.

Warranty process: When users find quality problems with EPDM granules, they should contact the supplier or manufacturer in time and handle them in accordance with their specified warranty process.

Q: Epdm Granule Track Maintenance Standards?

A: Cleaning: Regularly remove debris and dust on the surface of EPDM granules. You can use a soft brush or vacuum cleaner to ensure that the EPDM surface is clean.

A: Cleaning: Regularly remove debris and dust on the surface of EPDM granules. You can use a soft brush or vacuum cleaner to ensure that the EPDM surface is clean.

Inspection: Regularly check the status of EPDM granules, including changes in granule density, color, damage or wear, etc., and find and deal with problems in a timely manner.

Maintenance: Damaged or worn EPDM granules need to be repaired or replaced in time to ensure the smoothness and safety of the surface.

Prevent pollution: Avoid contamination of the surface of EPDM granules by oil, chemicals, etc., so as not to affect the performance and life of the granules.

Prevent UV exposure: EPDM granules are easily affected by ultraviolet rays, so care should be taken during daily maintenance to avoid prolonged exposure to the sun. This can be protected by covering or using sunscreen coatings.