EPDM vs TPE — Material Comparison & Project Selection

- Share

- publisher

- zoey

- Issue Time

- Dec 19,2025

Summary

Compare EPDM vs TPE granules for playgrounds, sports surfaces, and landscaping. Understand performance, durability, and cost to select the best material.

Introduction

Architects, contractors, and project owners often compare EPDM vs TPE, particularly EPDM granules for playgrounds, sports surfaces, and landscaping projects, because they want to avoid early fading, inconsistent elasticity, installation disputes, and premature resurfacing costs.

This article examines EPDM vs TPE from a project-risk and lifecycle-cost perspective, focusing on measurable data, automated production, and rigorous testing, which directly affect long-term surface performance and reduce project uncertainties.

Material Overview

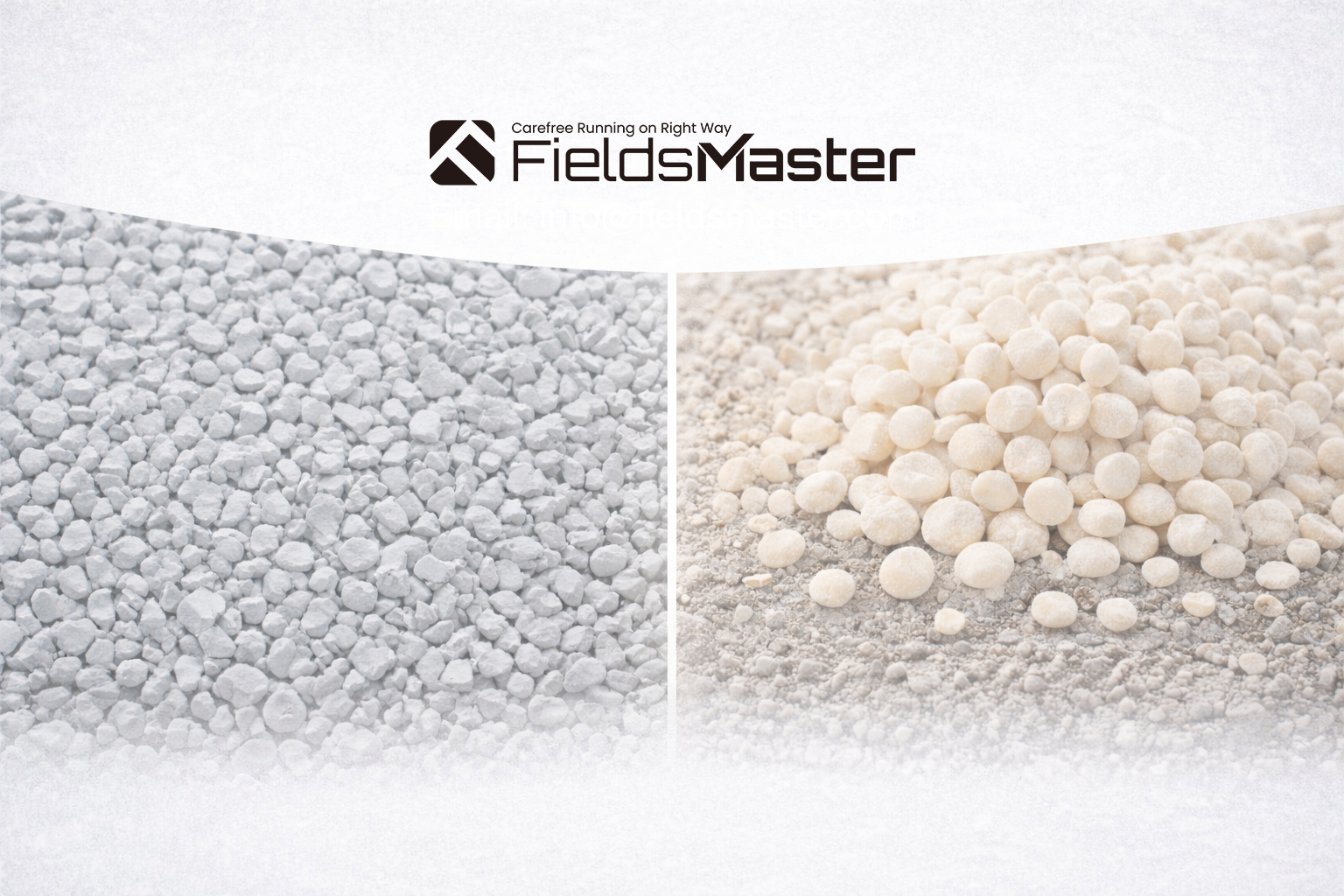

EPDM Rubber Granules

EPDM (Ethylene Propylene Diene Monomer) is engineered for outdoor applications, offering UV resistance, color stability, high elasticity, and shock absorption.

TPE Rubber Granules

TPE (Thermoplastic Elastomer) combines rubber-like elasticity with thermoplastic processing. Its performance depends on formulation and is best suited for indoor or semi-covered surfaces.

Technical Comparison

When evaluating EPDM granules vs TPE granules, it is important to consider long-term performance and environmental factors. Sports flooring rubber and playground materials must meet safety and durability requirements. /

| Property | EPDM | TPE |

| UV Resistance | Excellent | Moderate |

| Color Retention | High | Medium |

| Elasticity | Stable | Variable |

Heat & Cold Resistance | Broad range | Sensitive |

Lifespan | 8–15 years | 5–10 years |

Cost | Higher upfront | Lower initial |

Outdoor Performance

EPDM granules maintain color and elasticity under prolonged UV exposure and weather changes, making them ideal for playgrounds, sports surfaces, and landscaping. TPE granules are suitable for shaded or indoor areas but may degrade faster outdoors.

Safety & Environment

EPDM and TPE can meet safety standards if manufactured properly. EPDM’s long-term stability reduces maintenance frequency, minimizing lifecycle environmental impact.

Project Selection Guide

Choose EPDM granules for outdoor, long-lasting, and high-visibility projects. TPE is acceptable for indoor or short-term installations. Project owners benefit from predictable aging, consistent performance, and fewer maintenance issues.

FieldsMaster Advantages

1. Fully Automated Production: Over 90% of production steps automated, ensuring consistent particle size, color, and quality.

2. 5,000-Hour Accelerated Aging Test: Confirms long-term UV, color, and elasticity stability.

3. Strict Pre-Shipment Inspection: Every batch checked for particle size, color, and cleanliness.

4. Technical Support: Guidance on particle size, binder ratio, and installation to reduce failure risk.

Conclusion

Selecting the right rubber granule material requires balancing performance, durability, safety, and cost. EPDM granules from FieldsMaster provide data-backed reliability, long-term stability, and reduced lifecycle risk, making them ideal for playgrounds, sports surfaces, and landscaping projects. Contact FieldsMaster today to request samples or consultation and secure the best material for your project.